Machining Capabilities

Avanti Engineering’s Machining Capabilities

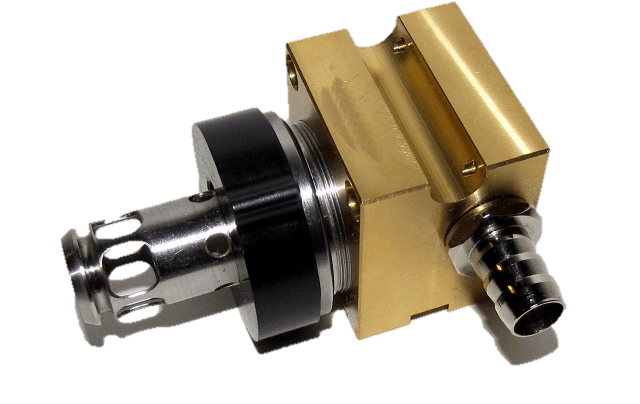

Avanti Engineering is a leading provider of machining services, specializing in both screw machine parts and precision CNC turning. With their extensive capabilities, they offer a high degree of flexibility to meet the unique requirements of each customer project. Some of the services Avanti offers are:

- Multi-axis CNC and Swiss CNC machining

- Multi-spindle high-speed screw machines

- In- house tool room including wire edm services

- Value-added consulting and engineering services including CAD/CAM

- ISO 9001:2015 (certified) Quality management system from design engineering to post-production

- CNC drilling, tapping, and milling services along with versatile secondary operations

- Light assembly

One of Avanti Engineering’s notable strengths is their multi-axis CNC and Swiss CNC machining capabilities. These advanced machining techniques allow for precise and intricate machining operations, enabling the production of complex components with tight tolerances. Whether it is a simple design or a highly intricate part, Avanti Engineering can handle the job with efficiency and accuracy.

Avanti Engineering operates multi-spindle high-speed screw machines. These machines are ideal for high-volume production, allowing for rapid and efficient parts manufacturing. With their in-house tooling, Avanti Engineering can further enhance their machining capabilities by providing wire electrical discharge machining (EDM) services. This technology allows for the precise shaping and cutting of materials, ensuring the highest level of accuracy and quality.

Avanti Engineering also offers value-added consulting and engineering services, including CAD/CAM. This means that they can assist customers with design optimization, ensuring that the machined components are not only functional but also cost-effective to produce. Their expertise in CAD/CAM allows for efficient programming and machining, reducing lead times and overall costs.

Quality management is a top priority at Avanti Engineering, as evidenced by their ISO 9001:2015 certification. From design engineering to post-production, they adhere to strict quality control measures to ensure that every component meets the highest standards. This commitment to quality gives customers peace of mind knowing that their parts will consistently meet the most precise specifications.

Avanti Engineering’s machining capabilities extend beyond CNC turning. They also offer CNC drilling, tapping, and milling services, along with versatile secondary operations. This includes processes such as deburring, threading, and surface finishing, allowing for the production of fully finished and ready-to-use components. Additionally, they provide light assembly services, further streamlining the manufacturing process for their customers.

No matter the industry or niche, Avanti Engineering is equipped to assist with precision-machining high-quality components. Whether it is for hydraulics, plumbing, aerospace, marine, electronics, medical, or any other sector, they have the expertise and capabilities to meet the specific needs of each project. With their worry-free approach to CNC machining, customers can trust Avanti Engineering to deliver exceptional results.

Contact Us today to find out how we can make your next CNC Machining project worry free!

Machining Capabilities

Automatic Bar Machining

CNC Turning

Custom Machining

Multi Spindle Machining

Screw Machine Products

Swiss Machining

High Volume Machining

CNC Milling

Ask a Question!

200 West Lake Drive

Glendale Hts, Illinois 60139

Phone: (630) 260-1333

Fax: (630) 260-1762

Looking for screw machine products or CNC Machining?

we have you covered!

AVANTI ENGINEERING, INC.

200 W. Lake Dr, Glendale Heights, IL 60139

(630) 260-1333

© 2023 Avanti Engineering. All Rights Reserved.