CNC, or computer numerical control, machining creates high volume precision turned parts and other parts for dozens of industries. CNC machining is ideal for companies looking for parts that are accurately designed and created using computers. Thanks to advancements of both the machines and computers, the process allows for intricate designs that can be consistently recreated with minimal variance.

Industries that Use CNC Machines

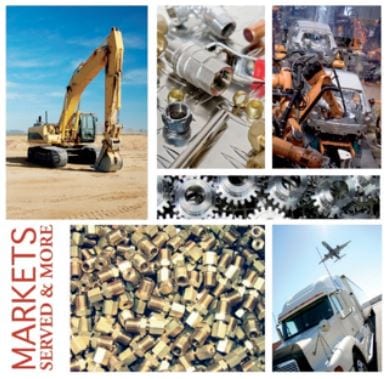

Many industries utilize CNC machines to create high volume precision turned parts and other parts. Let’s take a look at some of the most common applications these parts are required for:

Electronics

There is a trend of miniaturization within the consumer electronics industry. Components are continually becoming smaller, yet more powerful than before. The parts need to be compact and lightweight as well. Small scale CNC machining is perfect for handling the specialized materials that are needed for this. Examples of products created for electronics through CNC machines are:

- Electrical Insulation

- Housings for amplifiers

- Heat sinks

- Shielding against radio frequency interference

Medical

The medical field utilizes customized products that fit the needs of patients. Since most devices used in medical practices are disposable, these businesses need both high volume and precision. There are many types of CNC machines that work well for creating parts in this industry. Products made for medical businesses using CNC machines include:

- Research equipment

- Orthotic devices

- Various types of implants

- MRI machines

Aerospace

The aerospace industry has a vast need for repeatability and high accuracy. To ensure safety and compliance of critical parts, tolerances of just ±0.0001 are required. CNC machines are the perfect choice for this, as they are extremely precise. CNC machining services are great for creating everything from complicated bearing housings to high tolerance spacers. Here are some other aerospace parts made with CNC machines:

- Antennae

- Airfoils

- Bushings

- Parts for landing gear

Oil & Gas

Drilling rigs and refineries use large machines made with machined parts to ensure they fit perfectly together. If the fit isn’t precise, cylinders may not fill, pistons won’t create the right amount of pressure, and valves may leak. Hence, petrochemical companies use parts that have been CNC machined to ensure they fit exactly as needed. The oil and gas industry use parts created by CNC machines for rigs, refineries, and pipelines. Some examples are these components are:

- Drill bits

- Rods

- Pistons

- Valves

Marine

The marine industry is another example of businesses that rely heavily on parts created by CNC machining services. Just like airplanes, watercraft rely on highly-precise parts to keep them running and afloat. Not to mention all of the marine equipment that goes along with watercraft, such as underwater sensors, communication equipment, and more. Hence, CNC companies create many parts for boats, including:

- Propellers

- Components for the engine

- Insulating cases

- Prototype molds

CNC Machining Services

These are just a few examples of industries that use CNC machines. Other industries include defense, firearms, transportation, optical, and more. If you are in the market for such services, Avanti Engineering can help. Founded nearly 50 years ago, we are the #1 screw machine products manufacturer in the US! We specialize in high volume precision turned parts with an array of CNC machining and other services.