If you’ve ever wondered how machining with precision steel works, you’ve come to the right place. Here you’ll learn what it is, how it works, and the benefits it can provide to your manufacturing business. Precision steel is a special alloy that is used to make precision machined products, such as tooling and dies.

What Is Precision Machining?

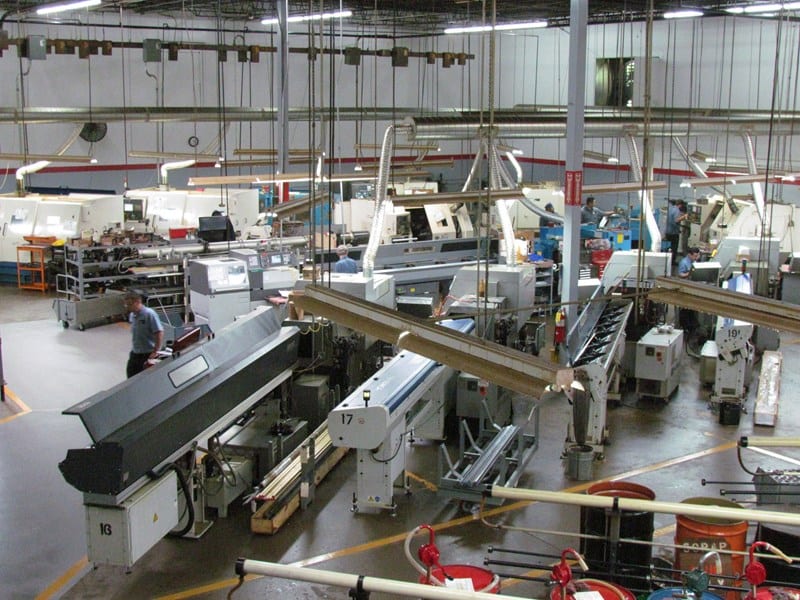

Precision machining is an important part of creating durable and precise tools and products. It allows for repeatability and accuracy in producing parts. This process starts with a large blank form and chisels away the material to reveal the final product. Precision machining also makes use of digital tools to automate the process. Today, CNC precision machining is common. It is a type of CNC manufacturing that uses computer-controlled machines to perform a series of complex operations. CNC machines are used to create precise parts by following instructions from computer-aided design (CAD) software. These programs help designers produce precise parts while improving the accuracy of the end product.

Precision machining is an advanced process that creates highly repeatable parts at high speeds. It is used in many industries, including aerospace, medical, automotive, and electronics. Precision steel machining requires skilled engineers with specialized knowledge of CAD and CAM programs. CNC milling and turning technicians have experience in each step of the process.

Why Choose Precision Steel?

When you need a precision machined part, the material you choose to use is important. The best choice depends on the material’s quality, cost, and performance requirements. Precision steel is a type of steel used in the manufacturing of high precision products such as aircraft parts, automotive parts, medical devices, and more. In addition, precision steel fabrication demands great accuracy. Parts that have irregular thickness or are made with inconsistent tolerances can cause problems for equipment. Precision steel is made up of two different metals – one that is strong and durable, and another that is flexible and lightweight. These two properties allow precision Steel to perform better than traditional steel products.

Other commonly used materials in precision machining include steel, aluminum, graphite, plastic, glass, and composites. A professional machinist can help you determine the right material to reach the tight tolerances. Stainless steel, for example, has high levels of chromium, making it an excellent choice for many applications. Stainless steel parts have a high corrosion resistance. Many metal parts are exposed to harsh environments, and corrosion can affect their functionality and safety. There are different metal alloys and when combined with a base metal and other elements, the metal composition changes.

How Does Precision Steel Machining Work?

Precision machining is a vital process when you need to produce components with high accuracy and repeatability. A precision piece will have high tolerances and a smooth surface finish. CNC milling and turning technicians must have advanced technical skills to ensure that each step is executed correctly. These procedures require a high level of engineering and design knowledge, as well as a high level of accuracy and durability. Precision steel machining is commonly used in aerospace and automotive applications where flaws can have catastrophic consequences. In the oil and gas industry, precision machining is essential for maintaining the integrity of parts and equipment. Machines in this industry must perform tasks with utmost accuracy, from connectors to sealastic nipples. There are also many types of nuts, adapters, stiffeners, and washers that must be accurate.

Precision machining services are a must for these industries, and it’s crucial to choose a reputable, certified company to get your job done. The process of precision machining consists of cutting off excess raw material from a piece. It involves many different tools, and the finished product is created to exact specifications and tolerances. In some cases, it will even include deburring or other surface deformations. This process can produce a wide variety of profile shapes, which makes it ideal for the production of high-quality components. Precision steel machining is a crucial part of modern manufacturing.

Benefits of Precision Steel

Precision steel is one of the most widely used materials for precision machining. This material is durable and effective, and comes in different varieties that meet the needs of different industries. Its corrosion resistance, light weight, and ease of machining make it an ideal choice for a variety of applications. Precision steel has been used by manufacturers for decades because it provides superior strength and durability while maintaining flexibility and light weight. Precision steel is also more environmentally friendly than other materials, as it does not require any additional energy to produce.

How Do You Know When Precision Steel is Right For You?

While you may think that machining is a simple task, a variety of factors play into whether precision steel is right for your next project. There are several ways to determine whether precision steel is right for you. First, consider what type of product you need to manufacture. If you need a material with exceptional strength and durability, then precision steel is an excellent choice. If you need something lightweight and flexible, then another option might be better suited for your application.

One of the most important factors to consider is machinability. If the material is too hard to machine, it could require additional labor or special equipment to complete the project. Additionally, many steels used for projects are not free-machining steels. These steels generally have a higher hardness and lower machinability rating than free-machining steels.

When choosing a material for machining, stainless steel is an excellent choice. Stainless steel is highly durable, efficient, and versatile, making it a great choice for many different types of machining jobs. Stainless steel is also available in different alloy steels, allowing you to choose the right material for the job.

Tolerance is another factor to consider. Tolerance refers to the amount of deviation from the cut value. Tight tolerance allows for a minimal deviation but requires slower machining than loose tolerance. Loose tolerance allows for a larger range of deviation but allows for faster machining.

There are many great choices when it comes to selecting a machine shop. At Avanti Engineering, our customer service is unmatched! Our CNC machining specialist produce precision metal products meeting the high quality standards of our customers. We have decades of experience in high volume machining. Contact our specialists today!