High-volume CNC machining solutions are becoming increasingly important in the modern manufacturing industry. With the global market for machine tools estimated to reach $93.9 billion USD by 2023, it is clear that this technology has a bright future. However, understanding why and how to use high-volume CNC machining solutions can be confusing for those who are new to this technology. This article will explore what high-volume CNC machining solutions are, the benefits of using these solutions, and why they are necessary for modern manufacturers.

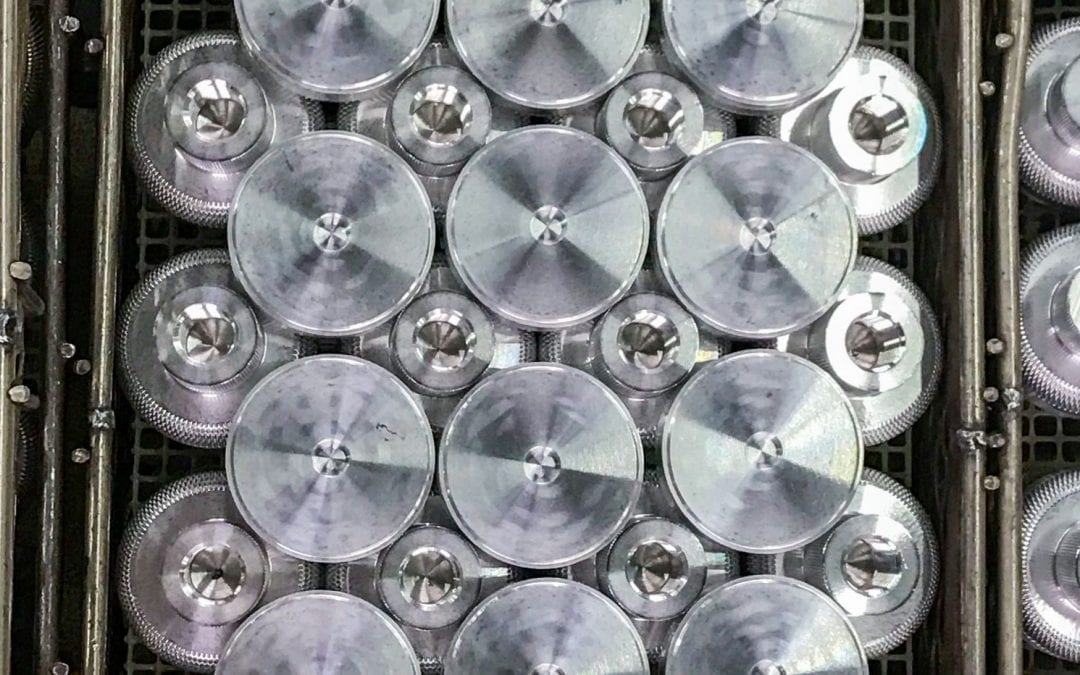

High-volume CNC machining solutions refer to a range of technologies that allow for multiple parts to be produced quickly and accurately through computer-controlled processes. These machines can process parts with extreme precision, ensuring repeatability and accuracy even when producing thousands or millions of pieces. Furthermore, they can be used to produce complex shapes which would otherwise require manual labor or expensive tooling costs.

The advantages of using high-volume CNC machining solutions include improved efficiency, cost savings, and flexibility. These machines are capable of producing parts more quickly than with traditional methods, reducing production time and speeding up delivery times. Moreover, the cost savings associated with reduced labor costs and the ability to produce parts without expensive tooling makes these machines an attractive option for manufacturers looking for ways to remain competitive in an increasingly crowded market. Finally, the flexibility offered by these machines allows manufacturers to create different types of products with minimal effort or downtime.

Reduce Lead Time And Cost Associated With Part Variations

Reducing lead time and associated costs for part variations is an important factor for any business, and high-volume CNC machining solutions provide just that. One way of achieving this is through on-time delivery of parts. Blanket ordering of precision-machined components enables businesses to have the required components when needed, reducing reliance on manual labor and avoiding costly machining processes. Additionally, CNC machining also ensures accuracy and repeatability as the same set of instructions is used for every iteration of a particular component, thus reducing the chances of human error.

This allows businesses to focus on other aspects such as designing new products or improving existing ones instead of worrying about production delays due to manual labor variability. Furthermore, with the help of CNC machining solutions, businesses can reduce their capital expenditure by eliminating additional labor costs such as overtime payments to machinists while ensuring high levels of quality control. All these advantages make it essential for businesses to consider using high-volume CNC machining solutions in order to keep production costs low and maintain efficiency in their operations. This opens up opportunities for them to move forward into more automated forms of manufacturing without having to worry about expensive and labor-intensive manual machining processes.

Avoid Labor Intensive And Costly Manual Machining Processes

High-volume CNC machining solutions are essential for avoiding labor-intensive and costly manual machining processes. In comparison to manual machining, CNC machining is much faster, more efficient, and more accurate. Additionally, CNC machines provide the ability to produce parts with high precision, repeatability, and consistency. Furthermore, CNC machines are able to produce complex parts with intricate shapes and dimensions in a short period of time, eliminating the need for spot buys due to longer lead times associated with manual machining processes.

CNC machines also offer significant cost savings in many ways. For example, CNC machines are capable of producing high-quality parts at a fraction of the cost associated with manual processes. Additionally, CNC machining eliminates the need for additional personnel training or safety measures as is required when using manual equipment. Moreover, utilizing CNC machinery can reduce production downtime due to its ability to quickly produce multiple parts without interruption or errors in quality control.

Finally, when considering an investment in high-volume CNC machining solutions it is important to consider all possible advantages such as reduced lead times and costs associated with part variations that can be gained from utilizing this technology. TIP: Investing in high quality CNC solutions can save you money over the long term by eliminating excess labor costs and increasing productivity within your organization.

High-volume CNC machining is suitable for a wide range of production needs. Whether you are producing small batches or large orders, this type of machining can help meet your production deadlines. The types of materials capable of being machined with high-volume CNC machines vary greatly, from plastics and metals to composites and alloys. Additionally, the turnaround time for manufacturing parts using high-volume CNC machines varies depending on the complexity of the part being produced but generally falls within an acceptable timeframe.

FAQs

Q1: What are the benefits of Avanti Engineering’s precision machining services?

A1: Avanti Engineering offers precision machining services that provide high-quality machining solutions for a broad range of markets. Our machining processes are designed to provide customers with high-volume, on-time delivery of precision machined components. We also offer blanket ordering for customers who require large-scale production runs.

Q2: How does Avanti Engineering ensure on-time delivery of precision machined components?

A2: At Avanti Engineering, we use the latest technology and processes to ensure on-time delivery of precision machined components. We also have a dedicated team of experienced engineers and technicians who are committed to delivering high-quality components on time, every time.

Q3: What types of machining solutions does Avanti Engineering offer?

A3: At Avanti Engineering, we provide machining solutions tailored to our customers’ needs. We can machine aluminum, steel, and stainless steel with precision accuracy. Our CNC machining services can take your project to the next level. We are committed to providing our customers with the highest quality of service, delivering top-notch results with every job.

Q4: What markets does Avanti Engineering serve?

A4: Avanti Engineering serves a broad range of markets, including aerospace, automotive, medical, and industrial. We are committed to providing our customers with high-quality precision machining solutions for their specific needs.

Q5: Does Avanti Engineering offer blanket ordering for large-scale production runs?

A5: Yes, Avanti Engineering offers blanket ordering for customers who require large-scale production runs. Our team of experienced engineers and technicians are committed to providing high-volume, on-time delivery of precision machined components.

At Avanti Engineering, our high-volume CNC machining solutions offer numerous benefits for our customers. From greater accuracy to faster production times and minimal maintenance requirements, the advantages associated with high-volume CNC machining make it an ideal solution for businesses seeking improved productivity and cost savings. It’s clear that high-volume CNC machining is one of the most efficient ways to create components with exceptional precision in record time – making it absolutely essential for businesses looking to stay competitive in today’s market. Contact the experts at Avanti Engineering to learn more about our on-time delivery of precision machined components.