In an era where precision and efficiency are paramount, the manufacturing landscape is experiencing a seismic shift, largely driven by the adoption of Swiss machining. This advanced manufacturing process is known for its meticulous accuracy. It has rapidly gained traction in fields requiring high-volume production of intricate parts.

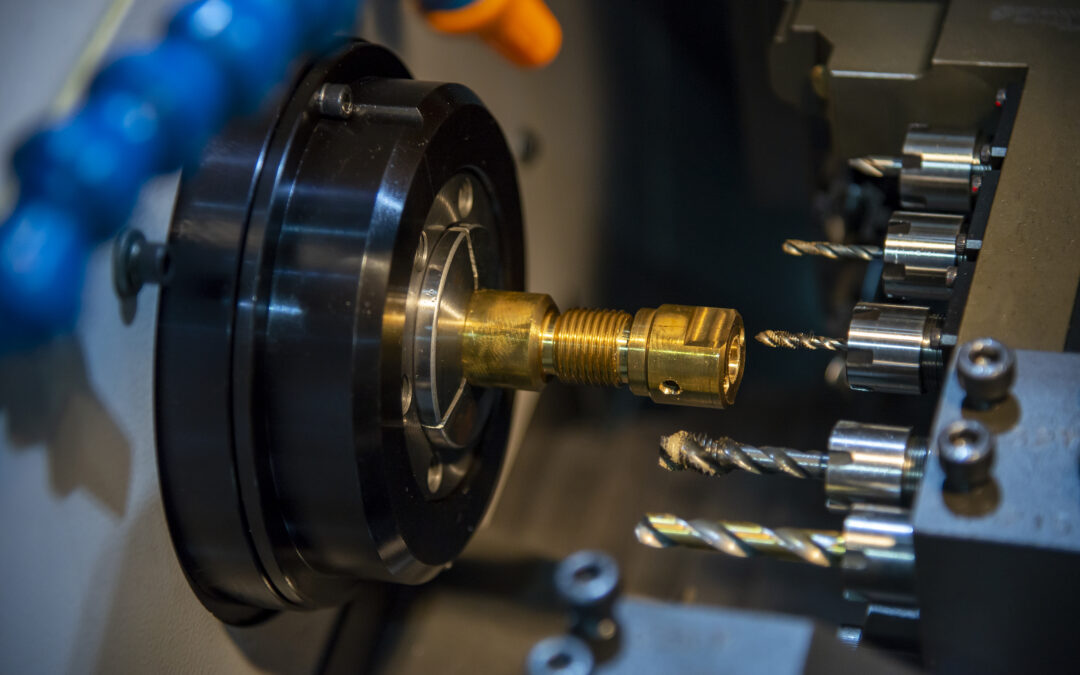

Swiss machining, a technique that marries 19th-century ingenuity with modern computer numerical control (CNC) technology, is increasingly meeting the call for exacting specifications in industries ranging from automotive to aerospace. Its capacity to support the workpiece throughout the process ensures unparalleled precision while its versatility in handling multiple operations simultaneously eliminates the need for secondary processing.

The profound impact of Swiss machining on manufacturing cannot be overstated. The questions then arise: how exactly is this technique reshaping the industry, and what potential does it hold for the future of manufacturing?

Benefits of Swiss Machining

Swiss machining, a revolutionary manufacturing approach, offers a multitude of benefits.

These benefits include a higher output of parts per cycle, faster processing of delicate parts, a reduction in secondary operations, and the capability to function across a broad range of diameters and lengths.

This technique leads to increased efficiency, with a greater number of parts produced per cycle compared to traditional CNC machines. By eliminating the need for secondary operations, Swiss machining offers a cost-effective solution to manufacturers.

The reduced set-up and processing time also contribute to overall cost effectiveness.

Given its ability to process delicate parts swiftly and its adaptability to various diameters and lengths, Swiss machining is perfect for industries requiring precision and flexibility in their manufacturing processes.

When to Utilize Swiss Machining

Determining the right time to utilize Swiss machining hinges on a variety of factors, including the desired completion of parts in a single cycle, the complexity of components, and the necessity for an unattended operation.

The advantages of Swiss Machining in the Medical Industry, for instance, come into play when producing intricate components like bone screws, dental implants or surgical tools. Swiss machining’s precision and speed yield high-quality results while minimizing the margin of error.

However, Swiss machining may present limitations for large scale production, particularly for larger parts. Although capable of mass producing small components, this technique may not be the most cost-effective or time-efficient for larger, less intricate items.

Deciding to utilize Swiss machining requires an analysis of technical requirements alongside production scale.

Industries Leveraging Swiss Machining

Harnessing the precision and efficiency of Swiss machining, a diverse range of industries – from automotive to aerospace – has realized significant advancements in their manufacturing processes. These industries are leveraging Swiss machining to achieve superior production outcomes, and offer high-quality products to their consumers.

Automotive Industry:

- Swiss machines play a crucial role in producing complex and precision parts like valves, bearings, and engine components.

- Benefits in the automotive sector include improved efficiency, precision, and cost-effectiveness.

Aerospace Industry:

- Swiss machining guarantees the production of intricate components with high accuracy, meeting the stringent standards of aerospace applications.

Medical Technology:

- Swiss machines are employed in manufacturing small, intricate, and quality-critical components such as surgical instruments and dental implants.

- This contributes to elevating the standard of healthcare solutions.

Understanding Swiss Machines Functionality

To fully understand the functionality of Swiss machines, one must explore their distinct structure and operational principles that transformed the manufacturing industry. Swiss machines vs. traditional CNC machines is a comparison that highlights the evolution of Swiss machining technology. Swiss machines, unlike their traditional counterparts, use a guide bushing to support the workpiece, minimizing deflection and enabling operations closer to the point of cut. This results in greater precision and stability, especially in long, slender workpieces.

| Aspect | Swiss Machines | Traditional CNC Machines |

| Precision | High | Lower |

| Complexity | Handles High | Less Capable |

| Operation Speed | Fast | Slower |

Swiss machines are also multi-functional, capable of simultaneous operations such as turning, drilling, and milling, thereby increasing productivity and reducing cycle time.

Advantages of Swiss CNC Machining

Embracing Swiss CNC Machining offers considerable advantages including time efficiency, precision, and cost-effectiveness, which have significantly transformed the landscape of the manufacturing industry. This methodology is instrumental in improving manufacturing processes and increasing production efficiency.

Time Efficiency:

- Swiss CNC Machining enables simultaneous operations, drastically reducing the cycle time.

Precision:

- The precision of Swiss CNC Machining is unparalleled. It has the capability to manufacture complex and delicate parts with high accuracy.

Cost-Effectiveness:

- By minimizing secondary operations, Swiss CNC Machining significantly reduces manufacturing costs.

Hence, Swiss CNC Machining provides an efficient, precise, and economical solution, making it a preferred choice for modern manufacturing units.

Frequently Asked Questions

What Is the History and Origin of Swiss Machining Technology?

Swiss machining originated in the 19th century, revolutionizing manufacturing with its sliding headstock design. Technological advancements have globally influenced industries, promoting efficient, precise production of complex components across a range of material types.

How Does Swiss Machining Compare to Other Manufacturing Technologies in Terms of Energy Efficiency and Environmental Impact?

Swiss Machining advancements yield significant environmental benefits by enhancing energy efficiency and reducing waste. Compared to other manufacturing technologies, it minimizes resource consumption, fostering a sustainable production process with less environmental impact.

What Specific Training or Qualifications Are Needed to Operate Swiss CNC Machines?

Operating Swiss CNC machines requires specialized training in machine operation, programming, safety measures, and maintenance. Certifications in CNC programming and machining can offer career advancement opportunities while ensuring efficient, safe, and quality production.

What Are the Maintenance Requirements for Swiss Machining Equipment?

Swiss machining equipment requires regular maintenance, including cleaning and lubrication, to extend equipment lifespan. Tooling costs can be managed effectively by performing routine checks to identify issues early and replace worn-out parts promptly.

Are There Any Limitations or Challenges Associated With Swiss Machining?

While Swiss machining offers remarkable precision, it can be cost-prohibitive for small-scale production due to the high initial investment. Additionally, its complexity requires highly skilled operators, posing a challenge in a market with a skills gap.

The Future of Manufacturing

In conclusion, Swiss machining indisputably stands at the frontier of manufacturing innovation. Like a master conductor leading a symphony, it orchestrates a flawless performance of precision, efficiency, and versatility.

It is the embodiment of modern manufacturing, offering unprecedented advantages and transforming industries.

As we venture deeper into the 21st century, Swiss machining will undoubtedly continue to shape and define the landscape of manufacturing, heralding a new era of unimagined possibilities.

If you’re ready to experience the power of Swiss machining firsthand, we invite you to work with Avanti Engineering and explore their exceptional machining services. With their expertise and state-of-the-art technology, Avanti Engineering can help you achieve superior results and propel your business to new heights. Contact Avanti Engineering today and discover the potential of Swiss machining for your manufacturing needs.