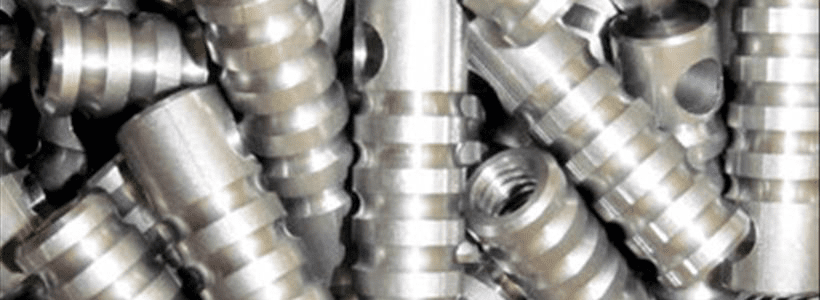

The number of applications for screw machine parts is growing every day, and the range of materials is getting wider. Among the most common types are steel alloys, which are made from iron and carbon, and are known for their high tensile strength. They’re a popular choice in a variety of industries, from construction to medical devices to household goods. Stainless steel is an extremely tough alloy, which makes it particularly popular for screw machine parts.

Metals used in screw machines are a range of materials, including brass, copper and stainless steel. Aluminum is a naturally occurring metal with high corrosion resistance and low density, making it ideal for construction and aerospace applications. Brass screws are a common choice and are durable, bright and corrosive-resistant. These types of parts are often found in plumbing and decorative applications. While most screws are manufactured from aluminum or stainless steel, they’re not limited to this type of material.

Screw machines don’t make screws. Rather, they are specialized machines that produce high-volume parts. They can be set up for hours or days at a time. Bar stock is typically fed into a collet, which is then machined to create a part. The part is separated from the bar stock and fed back into the collet to repeat the process. The process is time-consuming, but produces precise threads.

Traditional screw machine shops and CNC shops have distinct advantages and disadvantages. The former has a higher productivity level, while the latter is more flexible and easy to maintain. Its high level of flexibility means one operator can monitor several machines simultaneously. For many applications, screw machines have many advantages over their competitors. If you’re looking for a high-quality, high-volume, versatile machine, consider investing in a screw machine.

CNC machining is the most sophisticated and accurate way to make screw machine parts. CNC machining is a highly complex process that uses a lot of materials. In addition to CNC machines, manufacturers also need to consider the accuracy of their parts. In addition, a high-quality CNC screw can lead to more efficient production. However, it’s important to ensure the quality of a screw machine. If it’s important to your business, consider it an investment in a custom manufacturer.

In the modern world, a screw machine can produce small and medium-sized machined parts. These machines are fully automated and can produce high-volume parts. As long as it can run the process, it’s a viable solution for a wide variety of manufacturing applications. If you need to manufacture screws with a complex geometry, a screw machine is the best option. If you’re looking for a reliable source, Avanti Engineering has a state-of-the-art production facility with the latest CNC machining, turning, and milling machines. Contact us today for quality screw machined parts.