CNC machines make parts for nearly every industry around the world. These machines can make items out of all types of materials, including aluminum, plastic, metal, and other hard materials. CNC stands for “Computer Numerical Control,” but most people refer to them using the acronym.

What is a CNC Machine?

A Computer Numerical Control machine CNC machine is an automated motion control machine that manipulates machine shop tools using inputs programmed from a computer. In other words, this machine is controlled by a computer and used to create parts from solid materials into different shapes.

These machines were first created in the 1940s and 1950s. They relied on a technology called “perforated paper tape” or “punched tape.” This is a form of telecommunication data storage that’s long outdated. In fact, this data medium transitioned during the 1950s and 60s to analog, and then shortly after to digital computer processing.

How Much Does a CNC Machine Cost?

Generally speaking, CNC machines fit into one of two categories: novel machining technology and conventional machining technology. The cost of a CNC machine will depend on what type you choose and if you are buying new or used. The cheapest machines (milling machines) can run as low as $6,000, whereas the most expensive (Lathe) can cost upwards of $430,000. A CNC machine is a long term investment and machine shops take careful consideration before making a commitment to new equipment. Let’s take a look at the different technologies:

Novel Technologies

1. Chemical and/or Electrical Machining: Numerous novel technologies employ specialized techniques to cut materials. Examples of these machines include Electrochemical, Electron Beam, Ultrasonic, Electrical Discharge machining (EDM), and Photochemical machining. These technologies are generally very specialized and used in specific cases for mass-producing certain types of materials.

2. Other Cutting Mediums: Several additional novel technologies make use of different mediums to cut materials. Some examples of this technology include oxy-fuel cutting machines, water-jet cutting technology, laser cutting machines, and plasma cutting machines.

Conventional Technologies

1. Lathes: Lathes spin the material against drill bits, rather than having the drill bit spin and be put into direct contact with the material. Lathes usually make their contact by having the cutting tool move laterally until it touches the spinning material continuously.

2. Drills: This is the simplest form as the drills work by spinning the drill bit which moves until it comes into direct contact with the material.

3. Milling Machines: There’s no doubt these are the most common of all CNC machines used in modern times. They work through the use of cutting tools that remove materials from the stock unit.

CNC Machining Services

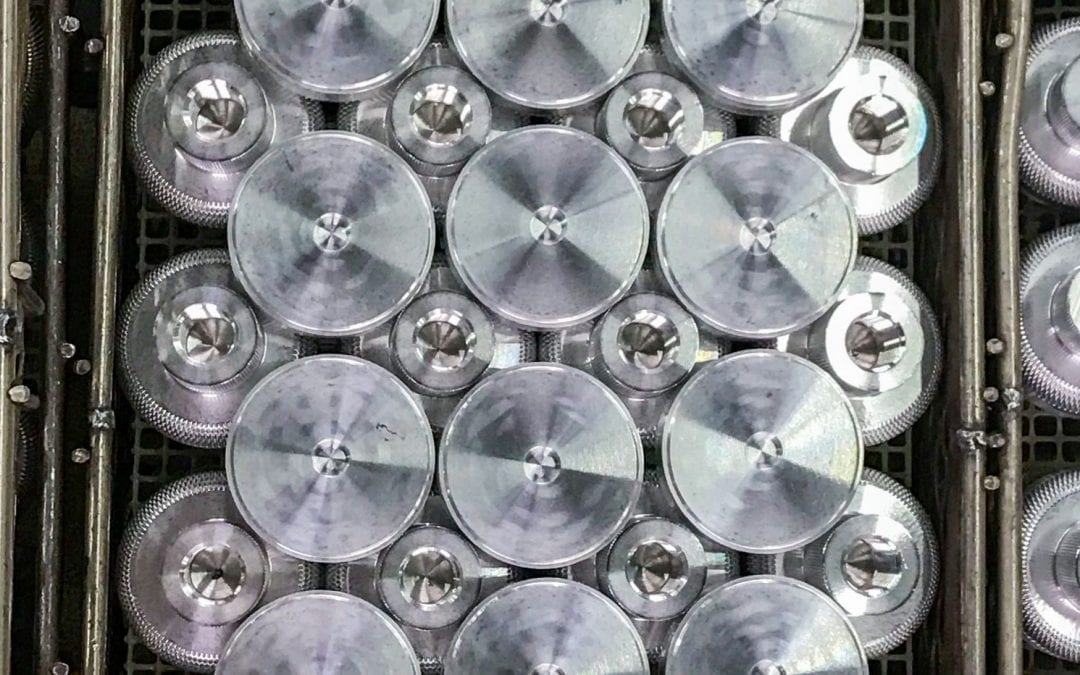

Due to the high cost of CNC machines, many companies opt for CNC machining services to supplement their manufacturing and production. At Avanti Engineering, we offer a wide range of screw-machining and precision turning services. We have CNC machining services for multiple high-speed operations with a single setup. In addition to our top-quality machines, even more value is added with our consulting and engineering services, including CAD/CAM.

Contact us today to learn how you can spare yourself from purchasing an expensive CNC machine.