Machining services with CNC machines include milling, turning, drilling, and more. In this article, we explain the scope of common types of CNC machining services.

What is CNC Machining?

The term ‘machining’ means using mechanical cutting technology to remove material through physical contact between the material and the tool. Computer Numerical Control Machining, or more commonly referred to as CNC machining, is the automation of the movement of machinery or factory tools. Pre-programmed software controls this automated movement. It is used to control a wide range of machinery like mills, grinders, lathes, routers, etc. CNC machining does not require multiple human interventions and it accomplishes three-dimensional cutting in just a single prompt.

Types of CNC Machining Services

The best CNC machining services use an array of machines that mill, turn, drill, or a combination of these techniques.

CNC Milling

Milling uses a rotating tool to cut and remove chips from the workpiece through physical contact. This technology is used for different functions like threading, slotting, and chamfering. It enables the production of complex and intricate designs on a single milling center. The accuracy of CNC milling is unmatched with tolerances as strict as +/- 0.1 mm. There are various sub-types under this CNC machining service, like Face Milling, Form Milling, Gear Milling, Profile Milling, and Surface Milling. These subtypes mill laterally, axially, or a hybrid of the two. The milling process can be used on different metals (steel, aluminum & brass) and plastics (Nylon, POM, HDPE, ABS, Polycarbonate, etc.)

CNC Turning or Lathing

CNC turning, also known as CNC lathing, is used to create cylindrical parts like shafts or bushings. The metal part spins while the CNC controls the cutting tool to move axially along the side, as well as to and from. The material around the circumference of the metal is removed, producing the desired shape and diameter. Turning can be done using a fixed head CNC machine or a sliding head CNC machine. The latter is used to reduce the final price and production time.

CNC Drilling

This CNC machining service is mainly used to create cylindrical holes in a workpiece by using multi-point drill bits. Both perpendicular and angular hole drilling can be achieved using this method. While perpendicular drilling is simply inserting the rotating drill bit into the workpiece using a CNC machine, angular drilling can get a little more complicated. For angular drilling, the use of clamping devices and specialized machined configurations are required. Tapping, Reaming, and Countersinking are a few operations that can be performed using CNC Drilling.

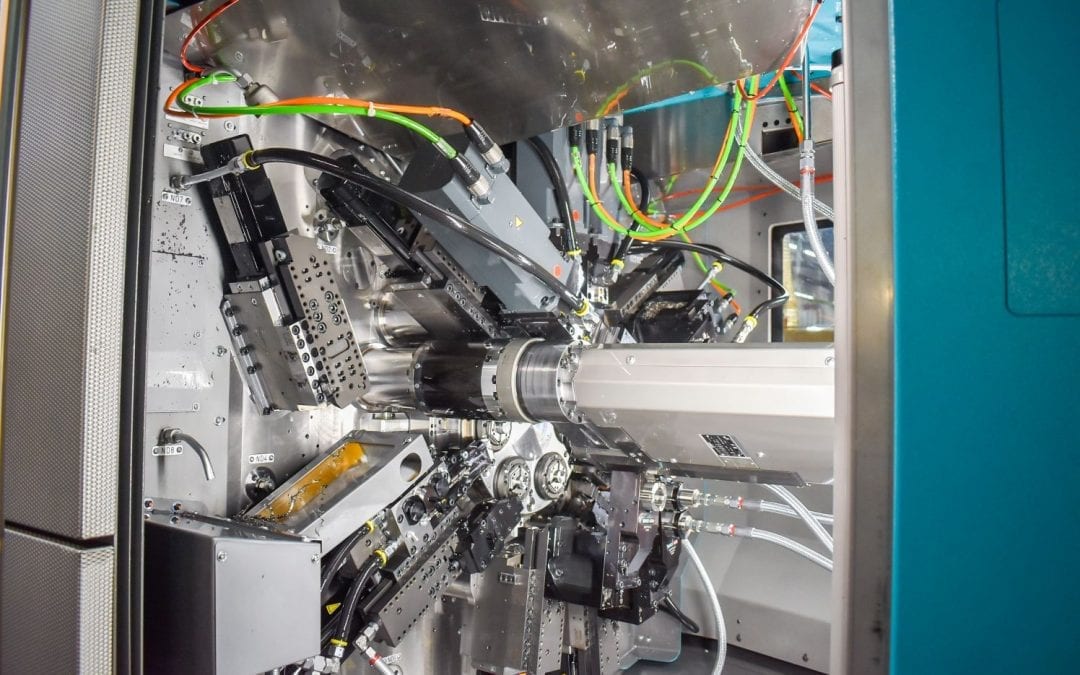

CNC Multi-Spindle Machining

A CNC Multi-Spindle machine has multiple spindles that are placed in a drum. This drum keeps changing its position, rotates horizontally, and completes many operations simultaneously. If not for the multiple spindles among which the work is divided, these operations would have to be carried out one after the other to complete the desired product. Now with every rotation of the drum, there is a part of the operation that is completed. Using multi-spindle CNC machining services or tools is more efficient and often more cost-effective than using multiple CNC machines.

Benefits of CNC Machining Services

Not only are there multiple types of CNC machining services that can cater to your different needs, but there is also a wide range of benefits from using CNC machining services like:

• Greater accuracy and precision in cutting

• Waste material reduction as a result of increased precision

• Less manual intervention resulting in reduction of labor and operating costs

• Consistency in the final product across huge volumes

• Improved production times resulting in higher volumes

Avanti Engineering is the #1 screw machine products manufacturer in the US. At Avanti, we keep our production facilities state-of-the-art by investing in the latest CNC machining, turning, and milling machines. Learn more about our CNC machining services.